Sheet Metal Deep Drawing

Sheet Metal Deep Drawing - 4.1 advantages of sheet metal drawing. Draw bead height and shape. The deep drawing process is a forming process which occurs under a combination of tensile and compressive conditions. 2.1 the deep drawing process. Fokus sheet metal, based in wembley, north west london is a family run business in operation for over 20 years. Web the deep draw sheet metal process is used to create a wide range of products, from simple cylindrical shapes to more complex geometries. Two main factors will cause the punch in deep drawing to draw the metal into the die cavity, rather than shearing it. Learn more about the services we offer. If the ratio of height to diameter of the product is greater than 0.5 then this drawing operation is known as deep drawing. Our specialist team has over 100 years combined experience in metal work.

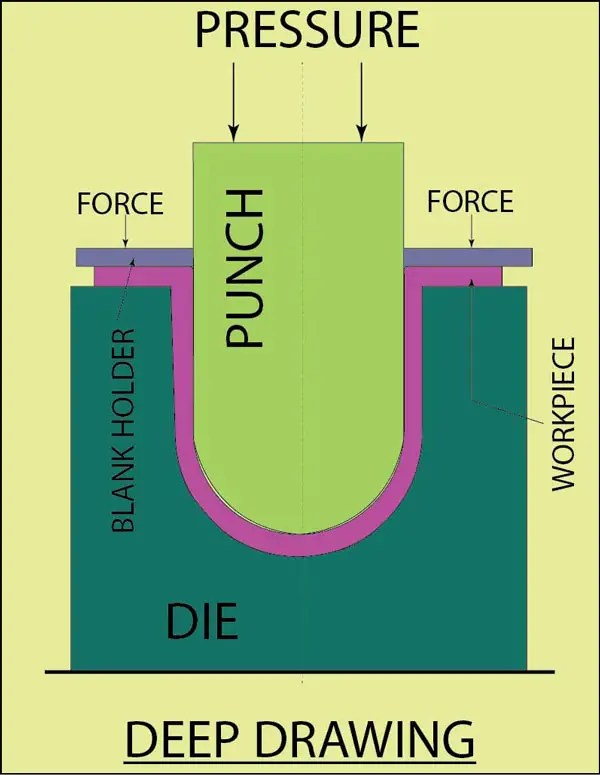

Drh fabrications create sheet metal and ductwork solutions tailored to exact project specifications. Draw bead height and shape. Importance of accurate sheet metal drawings. Types of deep drawing parts. Our expertise ensures accurate fabrication, resulting in components that fit precisely. Two main factors will cause the punch in deep drawing to draw the metal into the die cavity, rather than shearing it. Deep drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces.

Deep drawing specifically refers to producing parts whose draw depth (how deep the part is) is typically larger than its diameter or width. Deep drawing produces a part from a flat blank via the action of a punch force onto the blank. This process is the combination of metal forming process and sheet metal process. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius.

As mentioned, the punch and die setup is somewhat similar to a sheet metal cutting operation, such as punching or blanking. If the ratio of height to diameter of the product is greater than 0.5 then this drawing operation is known as deep drawing. Web deep drawing is a stamping process in which a flat sheet material is passed through a concave die under the pressure of a punch to form an open hollow part. Among various types of sheet metal components, deep drawing is often used to process various round simple parts, hemispherical and parabolic heads composed of larger or thicker. The process is considered deep drawing when the depth of the drawn part exceeds its diameter. Deep drawing specifically refers to producing parts whose draw depth (how deep the part is) is typically larger than its diameter or width.

The mold for deep drawing is been called deep drawing die. Learn more about the services we offer. Types of deep drawing parts. Two main factors will cause the punch in deep drawing to draw the metal into the die cavity, rather than shearing it. Web deep drawing (dd) is the sheet metal forming process which is used to produce containers from flat circular blanks.

Two main factors will cause the punch in deep drawing to draw the metal into the die cavity, rather than shearing it. Web what is deep drawing in sheet metal? Deep drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces. 4.2 limitations of sheet metal drawing.

The Process Is Considered Deep Drawing When The Depth Of The Drawn Part Exceeds Its Diameter.

Web step 1—calculate blank sizes. Two main factors will cause the punch in deep drawing to draw the metal into the die cavity, rather than shearing it. Draw bead height and shape. 3 applications and industries benefiting from deep drawing.

Deep Drawing Is A Sheet Metal Forming Process By Which A Sheet Metal Blank Is Slightly Clamped Along Its Perimeter By A Blank Holder And Radially Drawn Into A Forming Die By Use Of A Punch.

Because thicker materials are stiffer, they hold together better during deep drawing. Fokus sheet metal, based in wembley, north west london is a family run business in operation for over 20 years. Web deep drawing is one of the most widely used processes in sheet metal forming. Deep drawing produces a part from a flat blank via the action of a punch force onto the blank.

It Is Thus A Shape Transformation Process With Material Retention.

It is thus a shape transformation process with material retention. If the ratio of height to diameter of the product is greater than 0.5 then this drawing operation is known as deep drawing. Web deep drawing is a stamping process in which a flat sheet material is passed through a concave die under the pressure of a punch to form an open hollow part. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch.

Among Various Types Of Sheet Metal Components, Deep Drawing Is Often Used To Process Various Round Simple Parts, Hemispherical And Parabolic Heads Composed Of Larger Or Thicker.

Learn more about the services we offer. Web what is deep drawing in sheet metal? Founded by a father of three in 2001, fokus sheet metal is now an established family run business. As mentioned, the punch and die setup is somewhat similar to a sheet metal cutting operation, such as punching or blanking.